In the realm of electrical wiring, the unwavering adherence to specific standards and practices is paramount for ensuring safety, reliability, and optimal performance. Among these essential guidelines, the mandate that all metal clad cable conductors shall be stranded stands as a testament to the rigorous engineering principles that govern this critical component of electrical systems.

This article delves into the significance of this requirement, exploring the types, construction, properties, applications, and regulations surrounding all metal clad cable conductors.

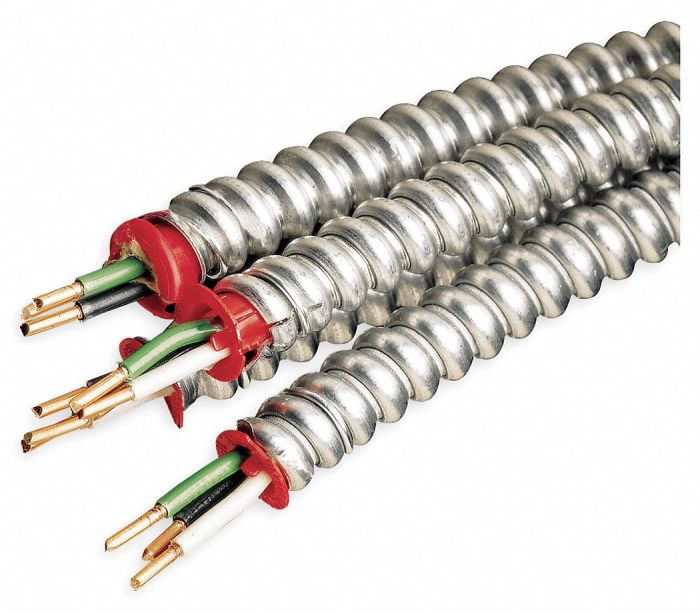

The construction of all metal clad cable conductors involves meticulously stranding individual metal wires together, creating a flexible and durable conductor that can withstand the rigors of various electrical applications. This stranding technique enhances the conductor’s resistance to mechanical stress, reduces the risk of breakage, and improves its overall flexibility, making it ideal for use in demanding environments.

Types of All Metal Clad Cable Conductors: All Metal Clad Cable Conductors Shall Be Stranded

All metal clad cable conductors are used in electrical wiring to provide a high level of protection against environmental factors and mechanical damage. They are typically made of copper or aluminum, and are clad with a layer of metal, such as steel or lead.There

are three main types of all metal clad cable conductors:

- Type AC: Type AC conductors are made of copper or aluminum, and are clad with a layer of steel. They are the most common type of all metal clad cable conductor, and are used in a wide variety of applications.

- Type MC: Type MC conductors are made of copper or aluminum, and are clad with a layer of lead. They are used in applications where there is a risk of corrosion, such as in underground installations or in wet environments.

- Type TC: Type TC conductors are made of copper or aluminum, and are clad with a layer of tin. They are used in applications where there is a need for a high level of conductivity, such as in power distribution systems.

The choice of which type of all metal clad cable conductor to use depends on the specific application. Factors to consider include the environment in which the cable will be installed, the voltage and current that will be carried, and the level of protection that is required.

FAQ

Why are all metal clad cable conductors required to be stranded?

Stranding enhances flexibility, reduces breakage risk, and improves resistance to mechanical stress.

What are the advantages of using stranded conductors in all metal clad cables?

Stranded conductors offer greater flexibility, durability, and resistance to fatigue.

What are the different types of all metal clad cable conductors?

Types include solid, stranded, concentric stranded, and compacted stranded conductors.

What are the applications of all metal clad cable conductors?

Applications include power distribution, industrial machinery, and high-temperature environments.